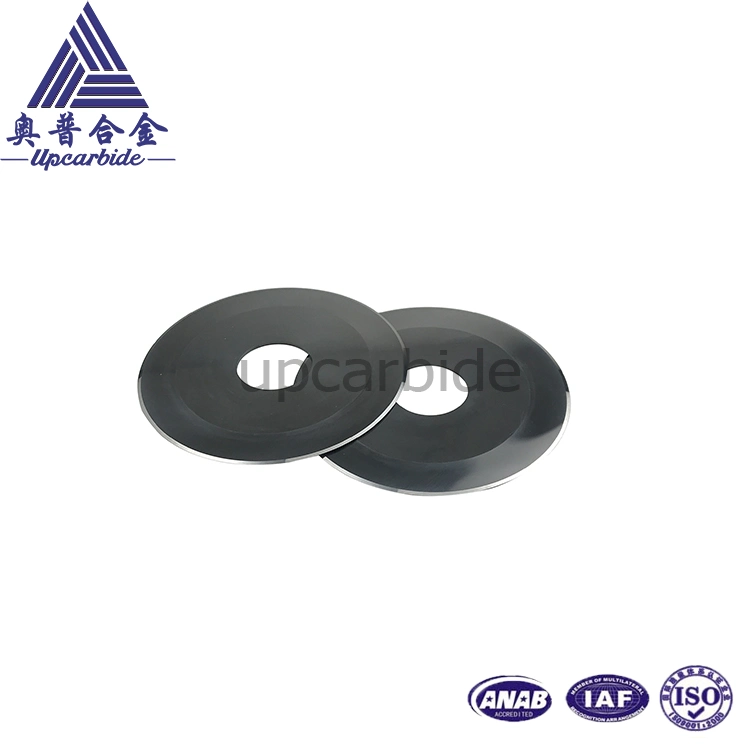

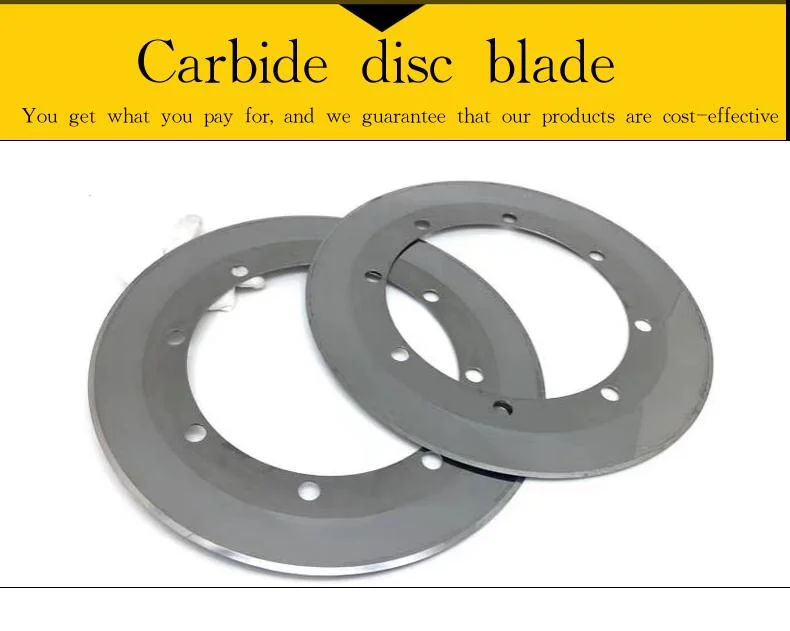

K10K20 Od90*ID25.5*1.2mm for Hardest Paper Cutting Tungsten Carbide Cutting Disc

Description

Basic Info.

| Model NO. | OD90*ID2*1.2mm |

| PCD | 100mm |

| ET | 15mm |

| Hole | 5 |

| Hardness | 89.5hra |

| Density | 14.8g/cm3 |

| Co | 8% |

| Wc | 92% |

| T.R.S | 2800MPa |

| Thickness | 1.2mm |

| Grain Sizes | Medium Grain Size |

| Grade | Yg8 |

| Inner Diameter | 26mm |

| Outer Diameter | 90mm |

| Transport Package | 25kg. Carton |

| Specification | OD90*ID26*1.2mm |

| Trademark | ZZUP |

| Origin | Zhuzhou, Hunan, China |

| HS Code | 820900100 |

| Production Capacity | 100000PCS/Month |

Product Description

K10K20 OD90*ID26*1.2mm for hardest paper tungsten carbide cutting disc

Specifications

tungsten carbide circular cutter,cemented carbide disc cutter,tungsten carbide cutter with teeth,hard alloy circular cutter,tungsten alloy disc cuttersuply all kinds of grades,according customer's request in size,manufacture high quality and compititive tungsten carbide circular cutter,cemented carbide disc cutter,hard alloy circular cutter,tungsten alloy disc cutter.1. promise the 100% virgin material .2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any sand hole.3. suply blank or polished sharpen blade carbide circular cutter4. more than 150 sets moulds for different sizes.5. Grades: YG6,YG6X,YG8,YG10X.YS2T etc for choosing.6. we can product the goods according your drawing and sizes.

Products Show

Grade specifications

| Grade | Density g/cm3 | T.R.S Mpa | Hardness HRA | Performance & application recommended | ISO code |

| YG6X | 14.9 | 1850 | 92 | Fine grain alloy, good wear resistance. Semifinishing of chilled cast iron, non-ferrors metals alloys, semi-finishing and finishing of hardened steel, alloy steel. | K10 |

| YG6 | 14.9 | 2450 | 90.5 | High wear resistance, bending strength, suitable for electronic industry with the disc cutting knife. | K10 |

| YG8 | 14.8 | 2450 | 90.5 | High strength ,impact and shock resistance higher than YG6X,,but wear resistance and cutting speed comparatively lower.Roughing of cast irons,non-ferrors metals and their alloys as well as non metallic materials at low cutting speed | K20 |

| YG10X | 14.7 | 2320 | 89.5 | High strength in use, impact and shock resistance higher than YG6, but wear resistance and cutting speed comparatively lower. Roughing of cast irons, non-ferrors metals and their alloys as well as | K40 |

| YS2T | 14.5 | 2200 | 91 | Fine grain alloy, good wear resistance. Used for processing hard wood,veneer board,PCB,PVC and metals. | M10 |

Sizes choosing:

| TYPE | OD(mm) | ID (mm) | S (mm) | TYPE | OD(mm) | ID (mm) | S (mm) | |

| Φ12×Φ6×S | 12 | 6 | 0.6-4.5 | Φ60×Φ19×S | 60 | 19 | 0.8-7.0 | |

| Φ13×Φ6×S | 13 | 6 | 0.6-4.5 | Φ63×Φ17×S | 63 | 17 | 0.8-7.0 | |

| Φ16×Φ6×S | 16 | 6 | 0.6-4.5 | Φ70×Φ22×S | 70 | 22 | 0.8-7.0 | |

| Φ22×Φ10×S | 22 | 10 | 0.6-4.5 | Φ75×Φ22×S | 75 | 22 | 0.8-7.0 | |

| Φ25×Φ12×S | 25 | 12 | 0.6-5.5 | Φ80×Φ22×S | 80 | 22 | 0.8-7.0 | |

| Φ32×Φ10×S | 32 | 10 | 0.8-5.5 | Φ83×Φ21×S | 83 | 21 | 0.8-7.0 | |

| Φ40×Φ10×S | 40 | 10 | 0.8-6.0 | Φ86.5×Φ21.5×S | 86.5 | 21.5 | 1.0-7.0 | |

| Φ45×Φ13×S | 45 | 13 | 0.8-6.0 | Φ90×Φ22×S | 90 | 22 | 1.0-7.0 | |

| Φ53×Φ13×S | 53 | 13 | 0.8-6.0 | Φ100×Φ22×S | 100 | 22 | 1.0-7.0 | |

| Φ52×Φ24.5×S | 52 | 24.5 | 0.8-6.0 | Φ125×Φ22×S | 125 | 22 | 1.0-7.0 | |

| Φ53×Φ24.5×S | 53 | 24.5 | 0.8-6.0 | Φ200×Φ70×S | 200 | 70 | 3.0-4.5 | |

| Φ55×Φ16×S | 55 | 16 | 0.8-6.0 | Φ250×Φ70×S | 250 | 70 | 3.0-4.5 | |

| Φ58×Φ22×S | 58 | 22 | 0.8-6.0 |

Packing details

Shipping ways

Production process

Our Contact